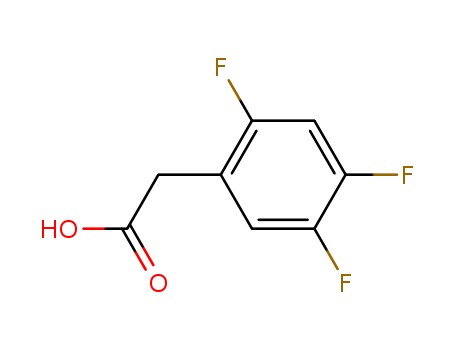

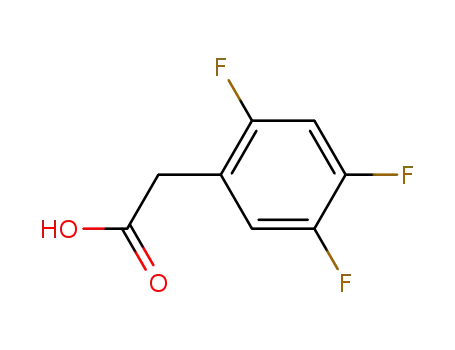

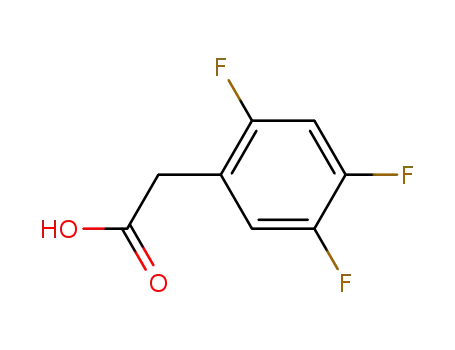

209995-38-0

- Product Name:2,4,5-Trifluorophenylacetic acid

- Molecular Formula:C8H5F3O2

- Purity:99%

- Molecular Weight:190.122

Product Details;

CasNo: 209995-38-0

Molecular Formula: C8H5F3O2

Appearance: white or off white power

Chinese Manufacturer Supply High Purity 99% 2,4,5-Trifluorophenylacetic acid 209995-38-0 Safe Transportation

- Molecular Formula:C8H5F3O2

- Molecular Weight:190.122

- Appearance/Colour:white or off white power

- Vapor Pressure:0.00866mmHg at 25°C

- Melting Point:121-125 °C

- Refractive Index:1.488

- Boiling Point:255 °C at 760 mmHg

- PKA:3.78±0.10(Predicted)

- Flash Point:108 °C

- PSA:37.30000

- Density:1.468 g/cm3

- LogP:1.73100

2,4,5-Trifluorophenylacetic acid (Cas 209995-38-0) Usage

|

Chemical Properties |

White to light brown solid |

|

Uses |

2,4,5-Trifluorobenzeneacetic Acid is used in the synthesis of EGFR/ErbB-2-kinase inhibitors. Also used in the synthesis of new imidazopyrazinone derivatives as potnetial dipeptidyl peptidase IV inhibitors. |

|

Application |

2,4,5-Trifluorophenylacetic acid is used to synthesize the intermediate of sitagliptin, a new drug for the treatment of type II diabetes. sitagliptin is a dipeptidyl peptidase-4 (DPP-4) inhibitor newly launched by Merck. It has good curative effect, small side effects, good safety and tolerance in treating type II diabetes. |

|

Preparation |

synthesis of 2,4,5-trifluorophenylacetic acid: A 100 mL flask was charged 10.0 g of 2,4,5-trifluoromandelic acid, 23.9 g of H3PO3 (6 eq.), 0.73 g of Nal (0.1 eq.) and 0.47 g (0.10 eq.) of MSA. The obtained mixture was stirred at 95-105°C for 24 hrs. Once the conversion is completed (by HPLC; conversion > 99%, typically achieved after 24 hours), the mixture is cooled to room temperature, and 20 mL of methyl tert-butyl ether were added and then 20 mL of water where added. The obtained mixture was stirred for 5 min, then the organic layers were separated. Then 10 mL of methyl tert-butyl ether was added to the aqueous layers, stirred for 5 min, then the phase were separated. The organic layers were combined. The combined organic layers were concentrated under vacuum at 35°C, to provide crude 2,4,5-trifluorophenylacetic acid(TFPAA). To the obtained crude TFPAA was recrystallized from toluene, to obtain TFPAA, as a white crystals, 6.4 g, molar yield 69.5%, chemical purity of HPLC 99.47% A/A% |

InChI:InChI=1/C8H5F3O2/c9-5-3-7(11)6(10)1-4(5)2-8(12)13/h1,3H,2H2,(H,12,13)

209995-38-0 Relevant articles

Efficient and Straightforward Syntheses of Two United States Pharmacopeia Sitagliptin Impurities: 3-Desamino-2,3-dehydrositagliptin and 3-Desamino-3,4-dehydrositagliptin

Matej Sova, Rok Frlan, Stanislav Gobec, and Zdenko Časar*

, ACS Omega 2020, 5, 10, 5356–5364

Interestingly, synthesis of impurity 9 was reported mainly starting from sitagliptin or late stage intermediates, (4,10) while only one four-step synthetic procedure from 2,4,5-trifluorophenylacetic acid was reported in a Chinese patent application. (12) Furthermore, two additional steps are needed if 2,4,5-trifluorophenylacetic acid is prepared from readily available 1,2,4,5-tetrafluorobenzene.

Rhodium/(2S,2'S,3S,3'S)-3,3'-Di-tert-butyl-4,4'-dimethoxy-2,2',3,3'-tetrahydro-2,2'-bibenzo[d][1,3]oxaphosphole (MeO-BIBOP) Catalyzed Synthesis of (R)-3-tert-Butoxy-carbonylamino-4-(2,4,5-trifluorophenyl)butyric Acid by Asymmetric Reduction of Enamines

Li Shenga, Haoling Gaoa,b,*(), Xufeng Wua,b, Gang Fana, Pengcheng Liua

, Chinese Journal of Organic Chemistry ›› 2021, Vol. 41 ›› Issue (5): 2105-2111

It is found that [Rh(NBD)2]+ BF−4 /(2S,2'S,3S,3'S)- 3,3'-di-tert-butyl-4,4'-dimethoxy-2,2',3,3'-tetrahydro-2,2'-bibenzo[d][1,3]oxaphosphole (MeO-BIBOP) catalyst has high stereoselectivity for the hydrogenation ofN-acetylenamine ester, reaching 99% ee. 2,4,5-Trifluorophenylacetic acid (1) was used as starting material, with Mildrum?s acid (2) through condensation, alcoholysis, condensation, amino acetylation, asymmetric hydrogenation, hydrolysis and amino protection to synthesize target product with 61% yield in total and 99.62% purity.

209995-38-0 Process route

-

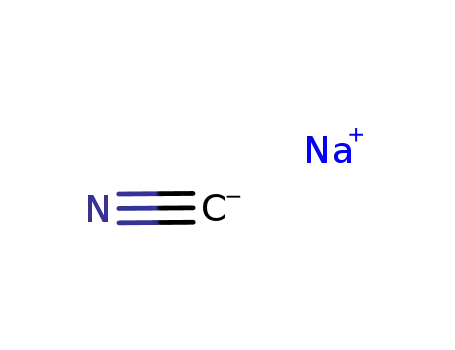

- 773837-37-9

sodium cyanide

-

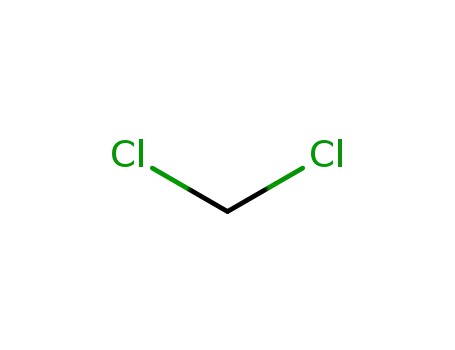

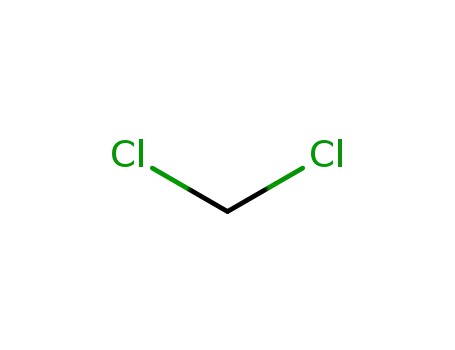

- 75-09-2

dichloromethane

-

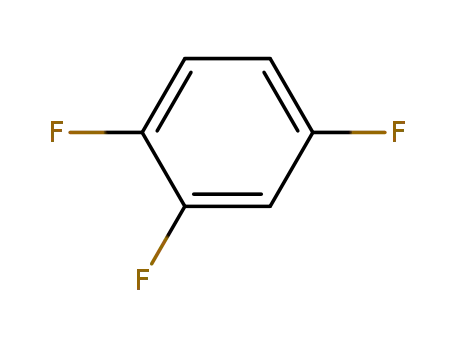

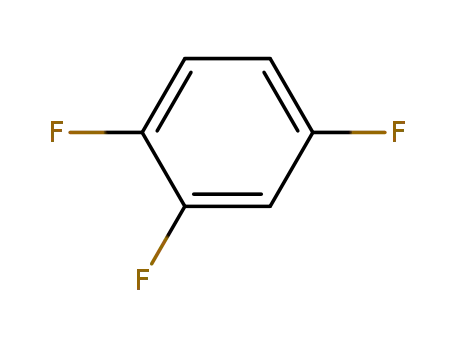

- 367-23-7

1,2,4-trifluorobenzene

-

- 209995-38-0

(2,4,5-trifluorophenyl)acetic acid

| Conditions | Yield |

|---|---|

|

sodium cyanide; With sodium stearate; nitrobenzene; sodium hydroxide; In water; at 115 ℃; for 0.75h; under 3420.23 Torr; Inert atmosphere;

dichloromethane; 1,2,4-trifluorobenzene; at 6 - 142 ℃; for 6h; under 2280.15 - 5320.36 Torr; Solvent; Pressure; Reagent/catalyst; Further stages;

|

99.2% |

-

-

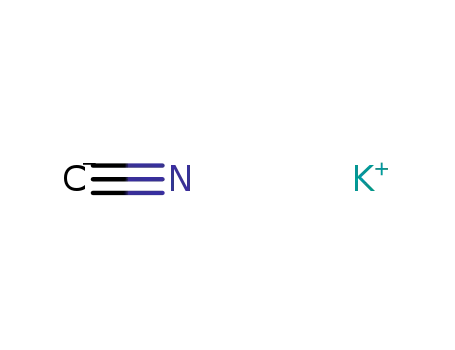

potassium cyanide

-

- 75-09-2

dichloromethane

-

- 367-23-7

1,2,4-trifluorobenzene

-

- 209995-38-0

(2,4,5-trifluorophenyl)acetic acid

| Conditions | Yield |

|---|---|

|

potassium cyanide; With sodium stearate; nitrobenzene; potassium hydroxide; In water; at 100 ℃; for 0.5h; under 2280.15 Torr; Inert atmosphere;

dichloromethane; 1,2,4-trifluorobenzene; at 6 - 130 ℃; under 2280.15 - 3800.26 Torr; Further stages;

|

98.2% |

209995-38-0 Upstream products

-

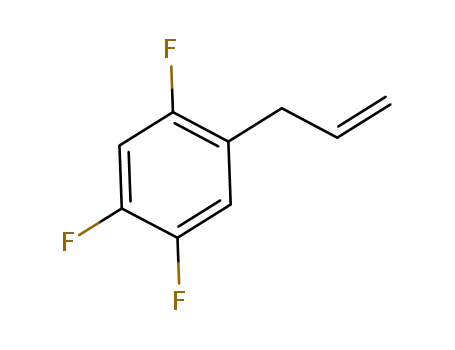

680993-47-9

1-allyl-2,4,5-trifluorobenzene

-

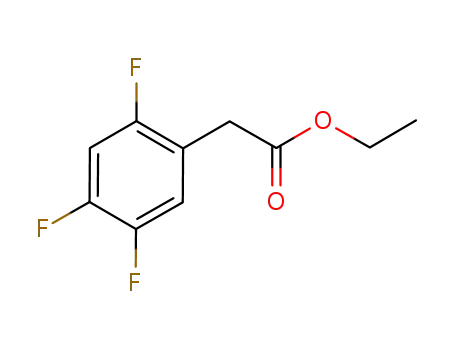

1256470-41-3

ethyl 2-(2,4,5-trifluorophenyl)acetate

-

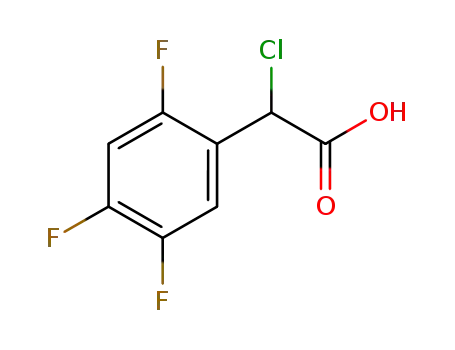

1036273-14-9

2-(2,4,5-trifluorophenyl)-2-chloroacetic acid

-

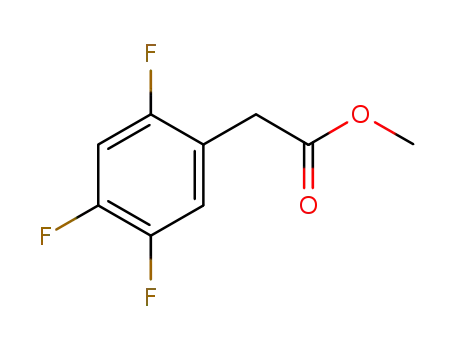

1036273-20-7

2,4,5-trifluorophenylacetic acid methyl ester

209995-38-0 Downstream products

-

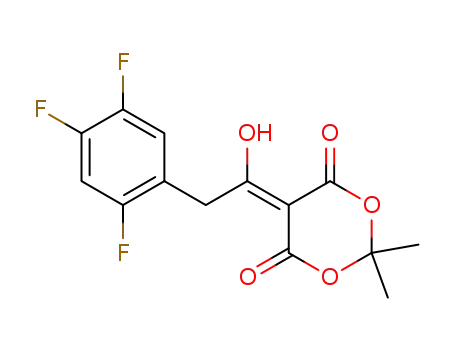

764667-64-3

5-(1-hydroxy-2-(2,4,5-trifluorophenyl)ethylidene)-2,2-dimethyl-1,3-dioxane-4,6-dione

-

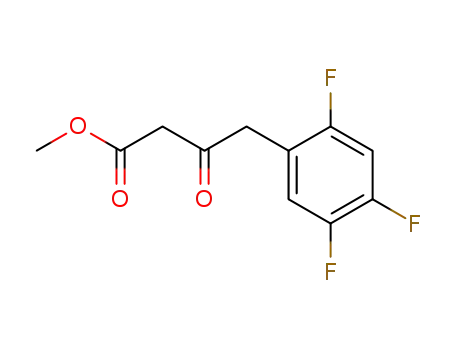

769195-26-8

4-(2,4,5-trifluoro-phenyl)-3-oxo-butyric acid methyl ester

-

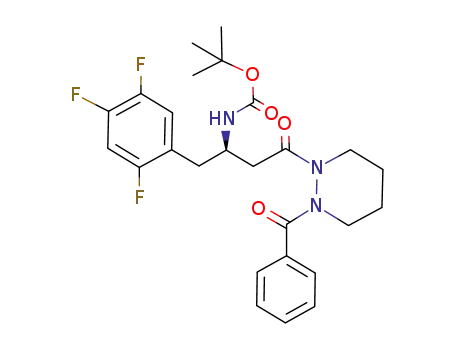

939964-30-4

(R)-[3-(2-benzoyltetrahydropyridazin-1-yl)-3-oxo-1-(2,4,5-trifluorobenzyl)propyl]carbamic acid tert-butyl ester

-

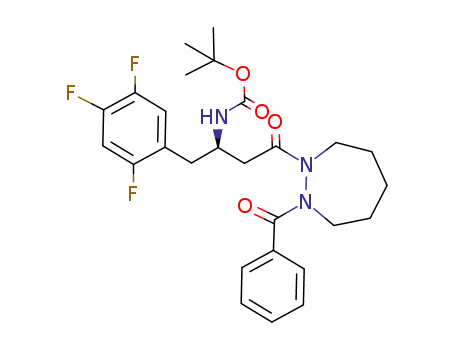

939964-31-5

tert-butyl (R)-4-(2-benzoyl-1,2-diazepan-1-yl)-4-oxo-1-(2,4,5-trifluorophenyl)butan-2-ylcarbamate

Relevant Products

-

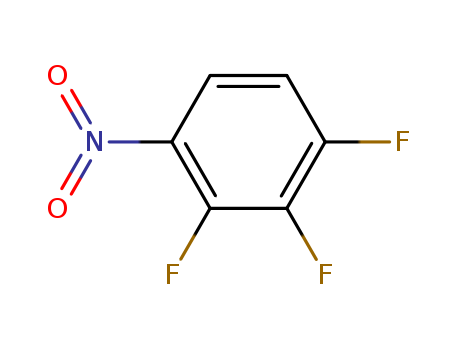

1,2,3-Trifluoro-4-nitrobenzene

CAS:771-69-7

-

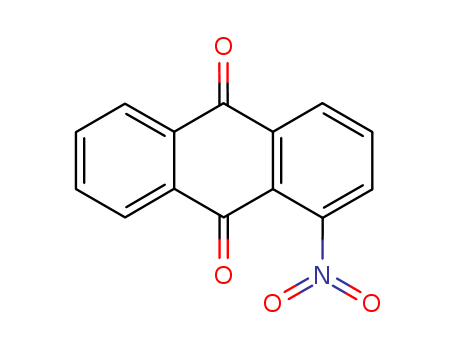

1-Nitroanthraquinone

CAS:82-34-8

-

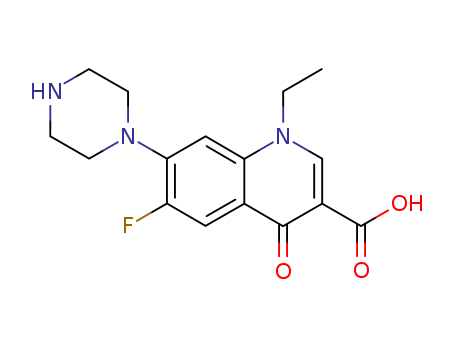

Norfloxacin

CAS:70458-96-7